At present, many users are familiar with the materials that uv flatbed printers can print. The main consideration is whether a printer can achieve the effect of multi-purpose machine. Whether the printing material is diversified, then we will give you a detailed introduction.

Print glass

Since the surface of the glass is smooth, it is a material that is difficult to print. It is necessary to do the coating treatment before printing, which can prevent the picture from falling off, fading, etc., improve the adhesion and ensure the printing effect is more beautiful. Print glass can print a variety of patterns.

Print tile

Due to the special use of ceramic tiles, printing patterns on ceramic tiles has always been a problem in the printing industry. Before printing ceramic tiles, it is necessary to do a coating treatment in order to better achieve waterproof, sunscreen and scratch-resistant printing effects.

Print phone case

At present, the demand for mobile phone casings on the market is still relatively large. Many people choose a patterned mobile phone case to protect their mobile phones. In the face of such a market, many businesses have joined the mobile phone casing printing and selling industry. However, many users are worried about how to choose a high-precision uv flatbed printer. Many manufacturers have purchased single-head printers on the market before. After using them, they find that such devices are not only slow but also accurate. Market demand.

Print leather

Leather printing has always been a problem in the leather printing industry because the leather is stretchable and the printed pattern is not perfect after being stretched. So be sure to pay attention to this when printing leather.

Print ad

The printing industry should apply the most printing, and the materials such as pvc and acrylic are often used in the advertising industry.

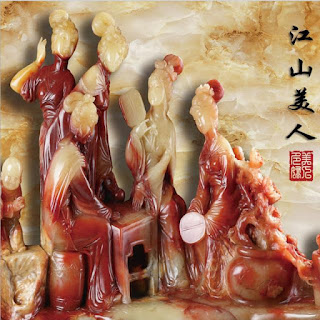

Printing rice paper and painting

At present, the amount of printing on rice paper and oil painting is still relatively large. If such a large quantity is only hand-painted, it will be a very big job. So choose the printer not to choose too small, choose too small print width supply and demand.

The materials that can be printed are not only those described above, but others can also print wooden boards, metal materials, cabinets, fans, glasses, etc. The uv flatbed printer is designed to accommodate more printing media.