UV flatbed printers are now more and more widely used in various production fields. If you don't understand maintenance, the machine will inevitably have a "temper".

How can I avoid them from malfunctioning as much as possible? Daily equipment maintenance is of course the most critical. Timely and effective equipment maintenance extends the life of UV flatbed printers and increases production efficiency. Let's learn together!

1, be careful of dust

Make sure the UV flatbed printer has a stable working platform and do not place anything on top of the UV flatbed printer.

The front cover must be closed during printing to prevent dust from entering the machine or other hard objects obstructing the movement of the printer trolley. It is forbidden to plug and unplug the printer cable. This will damage the printer's print port and the parallel port of the PC, which may even damage the motherboard of the PC. If the printout is not very clear, you can use the printer's automatic cleaning function to clean the printhead, but consume a small amount of ink. If the print is still not satisfactory after several consecutive cleanings, the ink may have run out and the ink cartridge needs to be replaced.

2. Ensure that the environment around the UV flatbed printer is clean and tidy.

Too much dust in the working environment can easily lead to poor lubrication of the guide shaft of the trolley, which hinders the movement of the print head during printing, causing inaccurate printing position or damage to the mechanical frame and crash. When the print head is not returned to the initial position and is turned back on, the printer first returns the print head to the initial position, and then the cleaning head operation is performed, so that unnecessary waste of ink is caused. The solution to this problem is to often wipe off the dust on the guide shaft and lubricate the guide shaft (use a better fluidity such as sewing machine oil).

3, the initial position

Before turning off the printer, return the print head to its original position (the printer automatically returns to the initial position when the printer is in the pause state). In order to avoid the waste of ink when the printer is re-cleaned at the next startup, the second is because the nozzle can be sealed by the protective cover at the initial position, so that the nozzle is not easily blocked.

4, often correct

Ink cartridges need to be rectified frequently: Anyone with experience in printers knows that the printer will correct the printer after reloading the cartridge or replacing it with a new one to improve print accuracy and print quality.

5, avoid daylight

The ink cartridge should be exposed to direct sunlight at room temperature when not in use for a long time. Because the ink evaporates quickly in this environment, it is easy to cause the nozzle to clog. In addition, in the low temperature and humidity environment, the print head circuit and the ink are prone to problems.

6, ink cartridges and gratings

When the ink cartridge is not used, it is best not to remove it to avoid wasting ink or the printer's metering error. Because the ink cartridge is refilled after the ink cartridge is replaced, the process will not work in the off state and the printer will not be able to detect the reinstalled cartridge. In addition, some printers measure the ink capacity by using an electronic counter inside the printer (especially in the statistics of the amount of color ink used). When the counter reaches a certain value, the printer judges that the ink is used up. During the cartridge replacement process, the printer resets its internal electronic counter to confirm that a new cartridge has been installed.

The grating strip of the UV flatbed printer should also be protected. Do not touch it with your hands. Do not let it stain with dust to prevent misalignment.

Guangzhou ChunYuQiuFeng Digital color printingequipment co.,LTD, which is heexecutants of double-white embossed high speed printing, first gloss oilsolution launched company in the domestic printing industries.

Monday, August 27, 2018

Sunday, August 26, 2018

UV Flatbed Printer With 3D Background Wall Part.2

Background wall UV printer features:

1. The printing effect is beautiful and the alignment is accurate and no scrap.

2. The printed format can be large or small. The common 600*600mm and 800*800mm tiles can be processed in the market, and the printing is completed once.

3. The printing cost is low, which can reduce the printing cost.

4. Strong stability, solves the shortcomings of common flatbed printers.

5. No need to make plate printing and repeat color registration, simple and convenient, can save more than 80% of the cost compared with the traditional process.

Common noun analysis:

Art flower carving: The art flower carving pattern content is mainly composed of lines and patterns. The pattern lines are mainly composed of modern lines, European patterns, object wire frames, etc. The conventional method is to engrave the pattern elements and then carry out artificial inkjet printing. Silver paint, the effect of this process on the bright surface material is high-grade and elegant.

Three-dimensional micro-carving: The three-dimensional micro-carving production process is rather cumbersome. It is necessary to carry out a very fine engraving process on the brick surface. After that, it is also required to make multiple films according to the pattern composition, and then accurately position the wall-mounted UV flatbed printer for 3D stereo high-definition inkjet. The final effect can achieve the effect of 1:1 ratio reduction oil brush touch, suitable for engraving of oil painting, upper freehand drawing and so on.

Flat color printing: The surface of the carved tile is coated, then inkjet printing is performed on the UV printer on the background wall, and finally a layer of varnish (or varnish) is applied on the surface to better protect the surface of the wall.

Symphony: Multi-layered engraving on the surface of the tile. After completion, there are a number of concave and convex layers and the theme part is all convex. The relief and the engraving can engrave the complex picture engraving and engrave multiple independent layers. The three-dimensionality of the picture is unmistakable and the expression is excellent.

Magical carving: Engraving on the surface of the tile, this is more complicated and requires a certain amount of technical content. After the engraving is completed, there are a plurality of different concave and convex layers, which have strong stereoscopic effect and good performance, and are suitable for various styles. The background wall image is engraved with a very fine detail, and the fine details in the pattern can be carved out. For example, the feathers of birds, the petals of flowers, the stamens, etc. in the paintings of flowers and birds, the carving requirements are high, and the production process is complicated.

Magical Art Carving: Art carving on the brick surface, suitable for the layered picture of the elements in the content, the art carving can engrave the three-dimensional and artistic sense of the theme part very carefully, generally retain some brick surface, the brick surface The combination of texture and picture makes the overall picture harmonious and integrated.

1. The printing effect is beautiful and the alignment is accurate and no scrap.

2. The printed format can be large or small. The common 600*600mm and 800*800mm tiles can be processed in the market, and the printing is completed once.

3. The printing cost is low, which can reduce the printing cost.

4. Strong stability, solves the shortcomings of common flatbed printers.

5. No need to make plate printing and repeat color registration, simple and convenient, can save more than 80% of the cost compared with the traditional process.

Common noun analysis:

Art flower carving: The art flower carving pattern content is mainly composed of lines and patterns. The pattern lines are mainly composed of modern lines, European patterns, object wire frames, etc. The conventional method is to engrave the pattern elements and then carry out artificial inkjet printing. Silver paint, the effect of this process on the bright surface material is high-grade and elegant.

Three-dimensional micro-carving: The three-dimensional micro-carving production process is rather cumbersome. It is necessary to carry out a very fine engraving process on the brick surface. After that, it is also required to make multiple films according to the pattern composition, and then accurately position the wall-mounted UV flatbed printer for 3D stereo high-definition inkjet. The final effect can achieve the effect of 1:1 ratio reduction oil brush touch, suitable for engraving of oil painting, upper freehand drawing and so on.

Flat color printing: The surface of the carved tile is coated, then inkjet printing is performed on the UV printer on the background wall, and finally a layer of varnish (or varnish) is applied on the surface to better protect the surface of the wall.

Symphony: Multi-layered engraving on the surface of the tile. After completion, there are a number of concave and convex layers and the theme part is all convex. The relief and the engraving can engrave the complex picture engraving and engrave multiple independent layers. The three-dimensionality of the picture is unmistakable and the expression is excellent.

Magical carving: Engraving on the surface of the tile, this is more complicated and requires a certain amount of technical content. After the engraving is completed, there are a plurality of different concave and convex layers, which have strong stereoscopic effect and good performance, and are suitable for various styles. The background wall image is engraved with a very fine detail, and the fine details in the pattern can be carved out. For example, the feathers of birds, the petals of flowers, the stamens, etc. in the paintings of flowers and birds, the carving requirements are high, and the production process is complicated.

Magical Art Carving: Art carving on the brick surface, suitable for the layered picture of the elements in the content, the art carving can engrave the three-dimensional and artistic sense of the theme part very carefully, generally retain some brick surface, the brick surface The combination of texture and picture makes the overall picture harmonious and integrated.

UV Flatbed Printer With 3D Background Wall Part.1

In the past five years, the material living standards of ordinary people have increased year by year, the income of urban residents has increased substantially, and the taste of consumer goods has been continuously optimized and upgraded. In terms of the layout of new houses, consumers are more concerned about decoration, especially 80. After the young people, they hope that the interior decoration can better match the home environment, have a distinctive theme, and the background wall is an important part of the interior decoration. The decoration industry will usher in a new high-speed development period, and the market demand will grow at a rate of 30% per year.

The tile wall industry is represented by Foshan, Guangdong and Yichun, Jiangxi. In the major cities in the interior, the background wall industry is developing rapidly. More and more people choose to invest in the wall project, and the tile wall is already in the country. The city has formed a certain scale of industry.

So what are the techniques for the tile wall? How is the tile wall made?

The process of tile wall is simple:

There are two main types of tile wall. The first one is the common flat color wall. The flat color refers to the process of directly processing the tile in the plane, with brightness and matte. The color carving background wall is mainly in engraving and color printing, and its surface is uneven. It is characterized by the feel of touch, lifelike, and the difference between light and matte. The following small series will step into the topic, to introduce you to these two processes.

[Flat Symphony Background Wall]

Required items: sand blasting machine + background wall UV flatbed printer + varnish

Production method:

Compared with the color-carved background wall, the flat color background wall omits many steps. It does not need to be engraved on the tile, and does not require an engraving machine. The production process is simple and convenient. The raw materials can be colored with irregularities, smooth surfaces, matte surfaces, and color lines, and the degree of image restoration is high. The resolution of Epson's UV printer is as high as 2880 dpi. Because there are glaze materials on the tiles, in order to better enhance the adhesion of the pattern, we can use a sand blasting machine to polish, then color the background wall UV printer, or can do a coating treatment on the tile surface, increase The ink absorbing ability of the tile enters the coloring process again. No matter how to increase the adhesion of the tile, the background wall UV printer can well produce the high-end, atmospheric and upper-grade background wall. Finally, depending on the customer's needs, you can choose whether or not to polish.

step:

Sandblasting machine (or coating treatment)

Background wall UV printer

Varnish treatment (this step can be omitted)

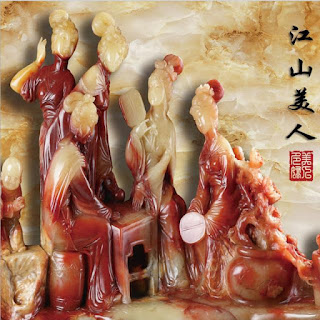

Common 3D, imitation jade, imitation marble and other background walls are flat color wall

[Color carved wall]

Required props: laser engraving machine + sand blasting machine + background wall UV flatbed printer + varnish

The color carving background wall adopts 600*600mm and 800*800mm tiles, including antique bricks, polished tiles, glazed tiles, microcrystalline stone bricks, etc., and all of them are presented through engraving machine (laser engraving machine or engraving machine) after laminating. The pattern is first engraved with the path, combined with sandblasting equipment (manual sand blasting machine or automatic sand blasting machine), the surface of the tile is sprayed off and the pattern part is sandblasted and polished. Sandblasting requires a certain degree of familiarity to form a three-dimensional effect. The depth of the color carving is required to be manually controlled by the sandblasting personnel. After the sandblasting, the pattern to be printed is input into the computer to make a vector image, and then the background wall UV flatbed printer is turned on! Form a real colorful carved tile background wall.

step:

1. Engraving machine engraving path

2. Sandblasting machine sandblasting

3. Background wall UV printer coloring

4. Polishing oil treatment (this step can be omitted)

The tile wall industry is represented by Foshan, Guangdong and Yichun, Jiangxi. In the major cities in the interior, the background wall industry is developing rapidly. More and more people choose to invest in the wall project, and the tile wall is already in the country. The city has formed a certain scale of industry.

So what are the techniques for the tile wall? How is the tile wall made?

The process of tile wall is simple:

There are two main types of tile wall. The first one is the common flat color wall. The flat color refers to the process of directly processing the tile in the plane, with brightness and matte. The color carving background wall is mainly in engraving and color printing, and its surface is uneven. It is characterized by the feel of touch, lifelike, and the difference between light and matte. The following small series will step into the topic, to introduce you to these two processes.

[Flat Symphony Background Wall]

Required items: sand blasting machine + background wall UV flatbed printer + varnish

Production method:

Compared with the color-carved background wall, the flat color background wall omits many steps. It does not need to be engraved on the tile, and does not require an engraving machine. The production process is simple and convenient. The raw materials can be colored with irregularities, smooth surfaces, matte surfaces, and color lines, and the degree of image restoration is high. The resolution of Epson's UV printer is as high as 2880 dpi. Because there are glaze materials on the tiles, in order to better enhance the adhesion of the pattern, we can use a sand blasting machine to polish, then color the background wall UV printer, or can do a coating treatment on the tile surface, increase The ink absorbing ability of the tile enters the coloring process again. No matter how to increase the adhesion of the tile, the background wall UV printer can well produce the high-end, atmospheric and upper-grade background wall. Finally, depending on the customer's needs, you can choose whether or not to polish.

step:

Sandblasting machine (or coating treatment)

Background wall UV printer

Varnish treatment (this step can be omitted)

Common 3D, imitation jade, imitation marble and other background walls are flat color wall

[Color carved wall]

Required props: laser engraving machine + sand blasting machine + background wall UV flatbed printer + varnish

The color carving background wall adopts 600*600mm and 800*800mm tiles, including antique bricks, polished tiles, glazed tiles, microcrystalline stone bricks, etc., and all of them are presented through engraving machine (laser engraving machine or engraving machine) after laminating. The pattern is first engraved with the path, combined with sandblasting equipment (manual sand blasting machine or automatic sand blasting machine), the surface of the tile is sprayed off and the pattern part is sandblasted and polished. Sandblasting requires a certain degree of familiarity to form a three-dimensional effect. The depth of the color carving is required to be manually controlled by the sandblasting personnel. After the sandblasting, the pattern to be printed is input into the computer to make a vector image, and then the background wall UV flatbed printer is turned on! Form a real colorful carved tile background wall.

step:

1. Engraving machine engraving path

2. Sandblasting machine sandblasting

3. Background wall UV printer coloring

4. Polishing oil treatment (this step can be omitted)

Wednesday, August 22, 2018

What Are The UV Flatbed Printer Application Industries?

UV flatbed printer, also known as universal flatbed printer or flatbed printer, breaks through the bottleneck of digital printing technology, and realizes a true printing, no plate making, full color image printing once, which has many advantages over traditional printing technology.

The original design and manufacture was mainly used for the printing of hard materials. It broke the limitation that inkjet technology can only print on soft materials. It is a major breakthrough in the history of inkjet technology, marking the entry of inkjet technology into multiple The birth of the field era. So what areas can UV flatbed printers be used in?

Packaging industry: alcohol (paper packaging printing, wooden packaging printing, metal packaging printing, PVC, packaging and printing, leather packaging printing, plexiglass packaging printing, etc.).

Decoration industry: background wall (tile wall, glass background wall, PVC gusset background wall, marble background wall, microcrystalline composite background wall, carved background wall) PVC gusset plate, PVC resin plate... Used by the industry

Digital industry: mobile phone case, TPU mobile phone case, mobile phone holster, notebook case, mobile power case, hard disk case, toy plastic case, set-top box case, etc.

Garment accessories: non-woven fabrics, T-shirts, buttons, leather, textiles, hangtags, etc.

Crafts: clocks, stone paintings, marble paintings, wedding photos, bluestone paintings, textile crafts, wooden crafts, metal crafts, stone crafts, art crafts, ceramic crafts, crystal crafts, advertising crafts, plexiglass Crafts, folk traditional crafts, oil paintings, and traditional local products.

Advertising industry: PVC card, plexiglass light box, KT board, PVC board, glass, signage, equipment operation panel, acrylic, PP board, PC board, badge, aluminum board, the entire advertising industry can be used.

Glass industry: art glass, glass partition, glass sliding door, glass background wall, frosted glass, transparent glass, plexiglass, tempered glass, glass curtain wall, etc.

Furniture and building materials: ceramic tiles, ceramics, wall tiles, waistline bricks, ceilings, ceilings, glass sliding doors, traditional doors and windows, personalized furniture, polyester panels, pressure panels, plywood, screens, wallpapers, coffee tables, ashtrays, etc.

Leather leather goods: leather, women's shoes, leather bags, handbags, travel bags, belts, etc.

Stationery gifts: pen case, notebook, wave board, dot reading machine, CD, metal business card holder, various material bookmarks, toys, etc.

Hardware and plastic: lighter, golf ball, silicone, digital photo frame, crystal, aluminum plate, metal plate, plastic products, tissue box, glasses frame, instrument panel, packaging box, toys, etc.

Footwear: women's shoes, EVA slippers, roller skates, shoe materials, printed shoes, leather printing, canvas shoes, hand-painted shoes, etc.

Electronic appliances: U disk, MP 3/ MP4/ MP5 player, computer case, home appliance, air conditioner, washing machine, rice cooker, mobile phone, crystal mobile phone case, electronic components, etc.

The original design and manufacture was mainly used for the printing of hard materials. It broke the limitation that inkjet technology can only print on soft materials. It is a major breakthrough in the history of inkjet technology, marking the entry of inkjet technology into multiple The birth of the field era. So what areas can UV flatbed printers be used in?

Packaging industry: alcohol (paper packaging printing, wooden packaging printing, metal packaging printing, PVC, packaging and printing, leather packaging printing, plexiglass packaging printing, etc.).

Decoration industry: background wall (tile wall, glass background wall, PVC gusset background wall, marble background wall, microcrystalline composite background wall, carved background wall) PVC gusset plate, PVC resin plate... Used by the industry

Digital industry: mobile phone case, TPU mobile phone case, mobile phone holster, notebook case, mobile power case, hard disk case, toy plastic case, set-top box case, etc.

Garment accessories: non-woven fabrics, T-shirts, buttons, leather, textiles, hangtags, etc.

Crafts: clocks, stone paintings, marble paintings, wedding photos, bluestone paintings, textile crafts, wooden crafts, metal crafts, stone crafts, art crafts, ceramic crafts, crystal crafts, advertising crafts, plexiglass Crafts, folk traditional crafts, oil paintings, and traditional local products.

Advertising industry: PVC card, plexiglass light box, KT board, PVC board, glass, signage, equipment operation panel, acrylic, PP board, PC board, badge, aluminum board, the entire advertising industry can be used.

Glass industry: art glass, glass partition, glass sliding door, glass background wall, frosted glass, transparent glass, plexiglass, tempered glass, glass curtain wall, etc.

Furniture and building materials: ceramic tiles, ceramics, wall tiles, waistline bricks, ceilings, ceilings, glass sliding doors, traditional doors and windows, personalized furniture, polyester panels, pressure panels, plywood, screens, wallpapers, coffee tables, ashtrays, etc.

Leather leather goods: leather, women's shoes, leather bags, handbags, travel bags, belts, etc.

Stationery gifts: pen case, notebook, wave board, dot reading machine, CD, metal business card holder, various material bookmarks, toys, etc.

Hardware and plastic: lighter, golf ball, silicone, digital photo frame, crystal, aluminum plate, metal plate, plastic products, tissue box, glasses frame, instrument panel, packaging box, toys, etc.

Footwear: women's shoes, EVA slippers, roller skates, shoe materials, printed shoes, leather printing, canvas shoes, hand-painted shoes, etc.

Electronic appliances: U disk, MP 3/ MP4/ MP5 player, computer case, home appliance, air conditioner, washing machine, rice cooker, mobile phone, crystal mobile phone case, electronic components, etc.

How to adjust the thickness of UV printer ink?

In the current market, consumers are fond of 3D murals, wallpaper wall coverings, three-dimensional craft paintings, crystal paintings and other prints with three-dimensional visual and three-dimensional feel, and also make the majority of UV printing processing plants profitable because Printing the above products is the specialty of UV printers, how to achieve it? In fact, by adjusting the inkjet thickness of the UV printer can be achieved!

Generally speaking, the color of UV printer is generally four colors, ie pure color (CMYK), five colors, color + white (CMYK+W), six colors, color + white + varnish (CMYK+W+V), eight colors, color + light red + light blue + white + varnish (CMYK + LM + LC + W + V), is the combination of these different colors, plus different print settings, constitutes a very powerful printing function of the UV machine, and print In the setting, the adjustment of the thickness of the ink is very important, mainly depends on three factors.

The first is the type of material and the background color. If the surface of the material is soft, the gap is large, and the background color of the material is dark, it is necessary to increase the amount of ink by 20%-40%;

Followed by the requirements of the picture, if the color of the picture is darker and the color requirements are more beautiful, it is necessary to appropriately increase the thickness of the ink;

Finally, we must look at the special requirements. If you are pursuing embossing effects, you can set the percentage of inkjet volume in the printing software, or you can set the number of printing passes to increase the thickness of the ink and achieve the relief effect.

UV printers increase the thickness of the ink, and an auxiliary function is the percentage of feathering. Usually it is between 0% and 200%. If the pattern printed by the system is more delicate and richer in color, you need to open the feathering function. The larger the value, the better the printing effect, but it will also reduce the production speed. The specifics should be determined according to the actual needs of the users.

It should be noted that the thickness of the UV printer ink is not as thick as possible. If the setting is unreasonable, it will also affect the color quality of the printed. Therefore, we must constantly explore and summarize according to our own needs, and we will make a work that is loved.

Generally speaking, the color of UV printer is generally four colors, ie pure color (CMYK), five colors, color + white (CMYK+W), six colors, color + white + varnish (CMYK+W+V), eight colors, color + light red + light blue + white + varnish (CMYK + LM + LC + W + V), is the combination of these different colors, plus different print settings, constitutes a very powerful printing function of the UV machine, and print In the setting, the adjustment of the thickness of the ink is very important, mainly depends on three factors.

The first is the type of material and the background color. If the surface of the material is soft, the gap is large, and the background color of the material is dark, it is necessary to increase the amount of ink by 20%-40%;

Followed by the requirements of the picture, if the color of the picture is darker and the color requirements are more beautiful, it is necessary to appropriately increase the thickness of the ink;

Finally, we must look at the special requirements. If you are pursuing embossing effects, you can set the percentage of inkjet volume in the printing software, or you can set the number of printing passes to increase the thickness of the ink and achieve the relief effect.

UV printers increase the thickness of the ink, and an auxiliary function is the percentage of feathering. Usually it is between 0% and 200%. If the pattern printed by the system is more delicate and richer in color, you need to open the feathering function. The larger the value, the better the printing effect, but it will also reduce the production speed. The specifics should be determined according to the actual needs of the users.

It should be noted that the thickness of the UV printer ink is not as thick as possible. If the setting is unreasonable, it will also affect the color quality of the printed. Therefore, we must constantly explore and summarize according to our own needs, and we will make a work that is loved.

13 Maintenance Tips For UV Printers

UV printer equipment presents a phenomenon of polarization in actual use. The first type of advertising production company machine did not take long, or it took only a few months, but it took a few years, and the machine was dirty and chaotic from the outside. In particular, the waste ink cartridge part of the machine is never cleaned. It is necessary to know that the ink is a chemical component and will change its quality for a long time. This position is the most common place for the core nozzle of our machine. Is harmful to the nozzle;

Another type of advertising production company used a few years to buy it for a few months. First of all, from the appearance, the machine is very clean and tidy, no ash, no paint, no machine scratches, no point at all. It is the old machine. From this point of analysis, the customer's machine is well maintained, because cleaning is the first step.

When it comes to maintenance, some advertising production companies are lack of energy, but some companies lack methods, they simply do not know how to maintain a delicate UV printer, and then share maintenance methods for your reference.

1. Do a good job of sanitation before starting the machine to prevent the damage of dust to the machine and the nozzle. The temperature of the air conditioner is controlled at about 25 degrees. There is no equipment for heating or dehumidification without air conditioning. Temperature and temperature are very important to the machine, and ventilation is required.

2, the boot should be operated in the correct order (first open the control software, see the daily operating procedures), pay attention to the method and sequence of wiping the nozzle. (Use a professional nozzle cloth for wiping the nozzle, and the inferior nozzle cloth will damage the nozzle!) Before pressing the ink, ensure that the valve is closed and the ink path is cut off. (The wiper should be wiped gently in one direction, and it is strictly forbidden to rub back and forth. The non-woven fabric of the nozzle is folded in half, and folded to a width of about one centimeter. When the color is wiped out after the nozzle is wiped, the non-woven fabric should be folded up, and another color should be rubbed in a clean place. The color of the nozzle is a thin plastic film on the surface of the nozzle, and the plastic film is peeled off, that is, the nozzle is scrapped).

3, when printing pictures, someone should be on duty (note that when the machine is wrong, you must first press the emergency stop switch at all angles of the machine to avoid further adverse consequences), and pay attention to the deformation of the raised plate is strictly prohibited to collide with the nozzle. Otherwise, it will cause permanent damage to the nozzle (paint, slag blocking the nozzle, nozzle film peeling off and scrapping).

4. Before shutting down every day, use a special cotton swab to pick up the cleaning solution and gently wipe the residual ink on the surface of the nozzle. Before closing, print a nozzle and check whether the nozzle is broken. If so, use a light-colored spot color to print, the color block is 10% - 20% solid color.

5, air pump, oil-water separator (including the main separator of the UV printer built-in small oil-water separator and air pump connection) to drain oil regularly (half a month);

6, UV lamp filter cotton should be replaced regularly, (otherwise it is easy to cause damage to the lamp, serious accidents and damage to the machine) filter cotton is related to UV lamp dust, heat. The ideal life of the lamp is about 500-800 hours, so it is necessary to make a record of daily use time;

7, UV printer shutdown should also respect the software priority order, first off the control software, then close the mapping software, then turn off the computer, then turn off the device, turn off all electrical equipment, secondary cartridge valve to remember to close, otherwise In the past two days, the ink has dried up, but now some manufacturers have a backup UPS power supply. After the machine power is turned off, the negative pressure system can be guaranteed to work normally. Of course, if conditions permit, it is better to let the machine not shut down. Always in the standby state, the effect can be large, and experienced people know that when the machine is working again the next day, there is no need to perform the action of starting the ink press, and it is known how expensive the ink is, and some of them are reluctant to press.

8. The front part of the car is covered with a cloth with better shading effect, which protects the nozzle from light and dust.

9, UV printer main filter and secondary filter should be replaced regularly (three months for a cycle). The ink pump should be inspected regularly, the ink pump does not rotate or the speed does not reach the demand of ink supply, that is, the ink supply motor continues to run, and the control software generally has a prompt: (the ink cartridge is in a state of lack of ink for a long time or the ink cartridge is in the state of ink supply for a long time) Replace it in time;

10. The moving parts of the UV flatbed printer should be regularly filled with oil and oiled. The X-axis Y-axis is a high-precision component. In particular, the X-axis portion with a high running speed is a consumable part. The X-axis conveyor belt should be inspected regularly to ensure proper tightness. The X-axis and Y-axis guide rails should be lubricated regularly. Excessive dust and dirt will cause excessive resistance in the mechanical transmission and affect the accuracy of moving parts. The oil injection of the guide rail includes: lubricating the rail portion and lubricating the lubricant in the slider portion;

11. Always check the ground wire (good for two ground wires) to ensure that it is safely grounded. It is forbidden to turn on the machine before the machine is connected to a reliable ground wire.

12. A regulated power supply (10KV) must be provided and ensure that it is working properly. Make sure the temperature and voltage supply is stable before starting the machine. UV flatbed printer lines should avoid using the same circuit as high-power electrical equipment, and regularly check whether the lines are worn or not;

13. When the machine is turned on and not printed, remember to turn off the UV lamp at any time. The purpose is to save power and the other is to extend the life of the UV class.

For the actual operation part, when the UV printer is required to install and debug the door, the technician actually guides the teaching.

Another type of advertising production company used a few years to buy it for a few months. First of all, from the appearance, the machine is very clean and tidy, no ash, no paint, no machine scratches, no point at all. It is the old machine. From this point of analysis, the customer's machine is well maintained, because cleaning is the first step.

When it comes to maintenance, some advertising production companies are lack of energy, but some companies lack methods, they simply do not know how to maintain a delicate UV printer, and then share maintenance methods for your reference.

1. Do a good job of sanitation before starting the machine to prevent the damage of dust to the machine and the nozzle. The temperature of the air conditioner is controlled at about 25 degrees. There is no equipment for heating or dehumidification without air conditioning. Temperature and temperature are very important to the machine, and ventilation is required.

2, the boot should be operated in the correct order (first open the control software, see the daily operating procedures), pay attention to the method and sequence of wiping the nozzle. (Use a professional nozzle cloth for wiping the nozzle, and the inferior nozzle cloth will damage the nozzle!) Before pressing the ink, ensure that the valve is closed and the ink path is cut off. (The wiper should be wiped gently in one direction, and it is strictly forbidden to rub back and forth. The non-woven fabric of the nozzle is folded in half, and folded to a width of about one centimeter. When the color is wiped out after the nozzle is wiped, the non-woven fabric should be folded up, and another color should be rubbed in a clean place. The color of the nozzle is a thin plastic film on the surface of the nozzle, and the plastic film is peeled off, that is, the nozzle is scrapped).

3, when printing pictures, someone should be on duty (note that when the machine is wrong, you must first press the emergency stop switch at all angles of the machine to avoid further adverse consequences), and pay attention to the deformation of the raised plate is strictly prohibited to collide with the nozzle. Otherwise, it will cause permanent damage to the nozzle (paint, slag blocking the nozzle, nozzle film peeling off and scrapping).

4. Before shutting down every day, use a special cotton swab to pick up the cleaning solution and gently wipe the residual ink on the surface of the nozzle. Before closing, print a nozzle and check whether the nozzle is broken. If so, use a light-colored spot color to print, the color block is 10% - 20% solid color.

5, air pump, oil-water separator (including the main separator of the UV printer built-in small oil-water separator and air pump connection) to drain oil regularly (half a month);

6, UV lamp filter cotton should be replaced regularly, (otherwise it is easy to cause damage to the lamp, serious accidents and damage to the machine) filter cotton is related to UV lamp dust, heat. The ideal life of the lamp is about 500-800 hours, so it is necessary to make a record of daily use time;

7, UV printer shutdown should also respect the software priority order, first off the control software, then close the mapping software, then turn off the computer, then turn off the device, turn off all electrical equipment, secondary cartridge valve to remember to close, otherwise In the past two days, the ink has dried up, but now some manufacturers have a backup UPS power supply. After the machine power is turned off, the negative pressure system can be guaranteed to work normally. Of course, if conditions permit, it is better to let the machine not shut down. Always in the standby state, the effect can be large, and experienced people know that when the machine is working again the next day, there is no need to perform the action of starting the ink press, and it is known how expensive the ink is, and some of them are reluctant to press.

8. The front part of the car is covered with a cloth with better shading effect, which protects the nozzle from light and dust.

9, UV printer main filter and secondary filter should be replaced regularly (three months for a cycle). The ink pump should be inspected regularly, the ink pump does not rotate or the speed does not reach the demand of ink supply, that is, the ink supply motor continues to run, and the control software generally has a prompt: (the ink cartridge is in a state of lack of ink for a long time or the ink cartridge is in the state of ink supply for a long time) Replace it in time;

10. The moving parts of the UV flatbed printer should be regularly filled with oil and oiled. The X-axis Y-axis is a high-precision component. In particular, the X-axis portion with a high running speed is a consumable part. The X-axis conveyor belt should be inspected regularly to ensure proper tightness. The X-axis and Y-axis guide rails should be lubricated regularly. Excessive dust and dirt will cause excessive resistance in the mechanical transmission and affect the accuracy of moving parts. The oil injection of the guide rail includes: lubricating the rail portion and lubricating the lubricant in the slider portion;

11. Always check the ground wire (good for two ground wires) to ensure that it is safely grounded. It is forbidden to turn on the machine before the machine is connected to a reliable ground wire.

12. A regulated power supply (10KV) must be provided and ensure that it is working properly. Make sure the temperature and voltage supply is stable before starting the machine. UV flatbed printer lines should avoid using the same circuit as high-power electrical equipment, and regularly check whether the lines are worn or not;

13. When the machine is turned on and not printed, remember to turn off the UV lamp at any time. The purpose is to save power and the other is to extend the life of the UV class.

For the actual operation part, when the UV printer is required to install and debug the door, the technician actually guides the teaching.

The Reason And Solution of UV Printer Flying INK

When we use uv printers, the most worrying problem is that we will encounter flying ink when printing patterns. It is well known that the products printed by uv printers are high-precision products, if flying ink appears when printing. Problems can cause the printed product to be unsatisfactory and affect the printing results.

So what is the cause of the printer flying ink? Is there any way to solve this problem? Here are some common reasons for the common use of uv universal flatbed printer nozzles and corresponding solutions.

Reason 1: UV printer equipment nozzle disconnection

Solution: Print the test strip to check the condition of the nozzle. If it is found to be blocked or faint, you need to clean the channel of the nozzle to keep it open.

Reason 2: UV printer nozzle is too far from the substrate

The reasonable height is generally below 10cm, the ejection force of different nozzles, and the distance from the substrate is between 1mm-20mm. If the spray range of the nozzle itself is exceeded, it will cause flying.

Solution: Reduce the distance between the nozzle and the substrate.

Reason 3: printer electronic control system

The electronic control system controls the pulse spacing of the nozzle ignition to be unreasonable.

Solution: Requires a technician to solve it. Buying UV printers from Black Mai Digital Technology, we will have an excellent after-sales team to solve the problem for you.

Reason 4: uv printer nozzle voltage is too high

The voltage displayed on the head panel indicator lights, whether it is red or not, alarm. If this happens, you need to lower the voltage of the nozzle.

Solution: If it is a modified circuit board, you need to change the circuit.

Cause 5: Static electricity generated during printing

When the environment is dry and the humidity is low, static electricity is generated, causing static electricity between the nozzle and the material.

Solution: Add a ground wire and add a static bar.

Along with the technological innovations of the entire industry, UV printers are becoming more widely used and are recognized by more corporate structures. If the uv printer has a problem of flying ink during the printing process, it will cause great trouble to the production efficiency. Once this problem occurs, it should solve the problem of flying ink of the UV printer in time, bringing higher efficiency to the production, and also for the user. Create value that far exceeds the device itself.

So what is the cause of the printer flying ink? Is there any way to solve this problem? Here are some common reasons for the common use of uv universal flatbed printer nozzles and corresponding solutions.

Reason 1: UV printer equipment nozzle disconnection

Solution: Print the test strip to check the condition of the nozzle. If it is found to be blocked or faint, you need to clean the channel of the nozzle to keep it open.

Reason 2: UV printer nozzle is too far from the substrate

The reasonable height is generally below 10cm, the ejection force of different nozzles, and the distance from the substrate is between 1mm-20mm. If the spray range of the nozzle itself is exceeded, it will cause flying.

Solution: Reduce the distance between the nozzle and the substrate.

Reason 3: printer electronic control system

The electronic control system controls the pulse spacing of the nozzle ignition to be unreasonable.

Solution: Requires a technician to solve it. Buying UV printers from Black Mai Digital Technology, we will have an excellent after-sales team to solve the problem for you.

Reason 4: uv printer nozzle voltage is too high

The voltage displayed on the head panel indicator lights, whether it is red or not, alarm. If this happens, you need to lower the voltage of the nozzle.

Solution: If it is a modified circuit board, you need to change the circuit.

Cause 5: Static electricity generated during printing

When the environment is dry and the humidity is low, static electricity is generated, causing static electricity between the nozzle and the material.

Solution: Add a ground wire and add a static bar.

Along with the technological innovations of the entire industry, UV printers are becoming more widely used and are recognized by more corporate structures. If the uv printer has a problem of flying ink during the printing process, it will cause great trouble to the production efficiency. Once this problem occurs, it should solve the problem of flying ink of the UV printer in time, bringing higher efficiency to the production, and also for the user. Create value that far exceeds the device itself.

How To Choose A UV Printer?

At present, with the rise of environmental protection printing, UV printing has received the attention of inkjet companies in the coming months. What kind of UV printers are good? Objectively speaking, UV printers of various manufacturers have their own advantages, and there is no absolute. Good, which one is absolutely bad. What kind of equipment is good? What suits you is the best. This issue of Xiaobian shares how to choose the right UV printer from three aspects.

The substrate is fundamental: different UV printers print different precision, pattern color, speed, consumable cost, and special effects. Then, when selecting equipment, customers should start from their own production, process requirements, and consumable expenses. Compared with multiple manufacturers, it is best to test various data on the spot so that you can choose better.

Service is king: the after-sales service provided by UV printers is king. Various sizes of problems occur during the use of the device. Regular manufacturers will provide professional training for 7-15 days before customers purchase equipment. On the one hand, it teaches customers how to use UV flatbed printers, and on the other hand, how to repair UV printers. Training videos such as text, video, and remote are also available during the later use.

The substrate is fundamental: different UV printers print different precision, pattern color, speed, consumable cost, and special effects. Then, when selecting equipment, customers should start from their own production, process requirements, and consumable expenses. Compared with multiple manufacturers, it is best to test various data on the spot so that you can choose better.

Service is king: the after-sales service provided by UV printers is king. Various sizes of problems occur during the use of the device. Regular manufacturers will provide professional training for 7-15 days before customers purchase equipment. On the one hand, it teaches customers how to use UV flatbed printers, and on the other hand, how to repair UV printers. Training videos such as text, video, and remote are also available during the later use.

10 Questions About Printheads You Need To Know Before Purchasing UV Printer

When you are buying a new UV Printer, you should ask some basic questions about its printhead.

1. Which brand and which type of printhead does the printer use?Most sellers will usually tell you the brand of the printhead when you ask for the printhead, not the detailed model of the printhead.For example, Ricoh nozzles commonly used in the market, Ricoh GEN5 nozzles and Ricoh GH2220 nozzles, Ricoh GEN5 nozzles are divided into water and oil, long and short lines, two channels and four channels.Second, is this printhead designed for solvent ink, or is it designed for UV ink?Some printheads were not originally made to print UV ink.

2.An early example of Epson sprinklers was an example. At the time, Epson itself did not produce UV-curable printers. Epson only produced water-based and solvent-based printers for photo printers and art. This does not mean that they cannot spray UV-curable inks, which only means that the nozzles may require special inks.Therefore, this question helps you understand whether the printhead is designed from the ground up for printing UV ink.

3. How many other printers use the same printhead? Do they have any questions?Konica Minolta nozzles, Ricoh nozzles, Kyocera nozzles, Xaar nozzles and starlight nozzles are all piezoelectric printheads. These are industrial strength piezoelectric printheads compared to Epson piezo printheads.

4. How many nozzles are there for each printhead?This can help you understand the speed or speed of your printer.

5. What is the total number of nozzles in the printer?The nozzle has a single nozzle that can only spray one color of the single color nozzle, and one nozzle can spray multiple colors of the multi-color nozzle.Take the Ricoh GEN5 nozzle as an example. It has two channels and four channels. When using it on a machine, you can print only one color for one nozzle, or two colors for one nozzle (two channels and four channels). Yes, you can print four colors (four-channel nozzle) in one nozzle.

6. How many printheads are there for each color?This will explain more about how slow or how fast your printer can eject ink.

7. How many skins are the ink droplets on the nozzle? Is there a variable droplet capability?The smaller the droplet, the better the print quality. However, a smaller drop size can slow down the printhead system. Similarly, printheads that produce larger drop sizes do not provide the same print quality, but print speeds tend to be better.

8. Is there a special white ink or varnish nozzle? Are they the same model as the CMYK printhead?Because the use of larger nozzles can make white inks better, some printers only have white ink to have "white droplet size is good". Other printers use the same header for any and all colors. For varnish, it is best to ask experienced printer operators and printer designers which head is best for varnish. Processing varnish is not as easy as handling ink. On a comparable basis, make sure your white ink has a recirculation system (otherwise white particles will precipitate and clog the nozzles).

9. If this piezoelectric head fails, who is responsible for paying the replacement head? What are the most common causes of printhead failure? What are the causes of the warranty? Which printhead failure causes are not covered by the warranty? Is there a limit to the number of printhead failures covered per unit time?In the case of a user-induced failure, most manufacturers will ask the user to pay for the replacement of the printhead. Most faults are indeed user errors, the most common cause being head impact.

10. What is the print height of the nozzle? Can I avoid nozzle impact?Impact is the most common cause of premature nozzle damage (improper media loading can cause bending, media rubbing onto a fragile nozzle plate, or not properly passing through the printer). A head impact can damage only a few nozzles, or it can damage the entire nozzle. Another reason is the continuous flushing, which can damage the nozzle system.

1. Which brand and which type of printhead does the printer use?Most sellers will usually tell you the brand of the printhead when you ask for the printhead, not the detailed model of the printhead.For example, Ricoh nozzles commonly used in the market, Ricoh GEN5 nozzles and Ricoh GH2220 nozzles, Ricoh GEN5 nozzles are divided into water and oil, long and short lines, two channels and four channels.Second, is this printhead designed for solvent ink, or is it designed for UV ink?Some printheads were not originally made to print UV ink.

2.An early example of Epson sprinklers was an example. At the time, Epson itself did not produce UV-curable printers. Epson only produced water-based and solvent-based printers for photo printers and art. This does not mean that they cannot spray UV-curable inks, which only means that the nozzles may require special inks.Therefore, this question helps you understand whether the printhead is designed from the ground up for printing UV ink.

3. How many other printers use the same printhead? Do they have any questions?Konica Minolta nozzles, Ricoh nozzles, Kyocera nozzles, Xaar nozzles and starlight nozzles are all piezoelectric printheads. These are industrial strength piezoelectric printheads compared to Epson piezo printheads.

4. How many nozzles are there for each printhead?This can help you understand the speed or speed of your printer.

5. What is the total number of nozzles in the printer?The nozzle has a single nozzle that can only spray one color of the single color nozzle, and one nozzle can spray multiple colors of the multi-color nozzle.Take the Ricoh GEN5 nozzle as an example. It has two channels and four channels. When using it on a machine, you can print only one color for one nozzle, or two colors for one nozzle (two channels and four channels). Yes, you can print four colors (four-channel nozzle) in one nozzle.

6. How many printheads are there for each color?This will explain more about how slow or how fast your printer can eject ink.

7. How many skins are the ink droplets on the nozzle? Is there a variable droplet capability?The smaller the droplet, the better the print quality. However, a smaller drop size can slow down the printhead system. Similarly, printheads that produce larger drop sizes do not provide the same print quality, but print speeds tend to be better.

8. Is there a special white ink or varnish nozzle? Are they the same model as the CMYK printhead?Because the use of larger nozzles can make white inks better, some printers only have white ink to have "white droplet size is good". Other printers use the same header for any and all colors. For varnish, it is best to ask experienced printer operators and printer designers which head is best for varnish. Processing varnish is not as easy as handling ink. On a comparable basis, make sure your white ink has a recirculation system (otherwise white particles will precipitate and clog the nozzles).

9. If this piezoelectric head fails, who is responsible for paying the replacement head? What are the most common causes of printhead failure? What are the causes of the warranty? Which printhead failure causes are not covered by the warranty? Is there a limit to the number of printhead failures covered per unit time?In the case of a user-induced failure, most manufacturers will ask the user to pay for the replacement of the printhead. Most faults are indeed user errors, the most common cause being head impact.

10. What is the print height of the nozzle? Can I avoid nozzle impact?Impact is the most common cause of premature nozzle damage (improper media loading can cause bending, media rubbing onto a fragile nozzle plate, or not properly passing through the printer). A head impact can damage only a few nozzles, or it can damage the entire nozzle. Another reason is the continuous flushing, which can damage the nozzle system.

Monday, August 20, 2018

Can I print tiles with a uv printer?

UV flatbed printer, also known as universal flatbed printer or flatbed printer, breaks through the bottleneck of digital printing technology, and realizes a true printing, no plate making, full color image printing once, which has many advantages over traditional printing technology.

With the innovation of technology, it has been printed in all the flat materials such as glass industry, ceramic tile industry, packaging industry, advertising production, acrylic sheet, carpet printing, mobile phone shell printing, grating plate, PVC board, canvas, Thangka, etc. The scope of application is extremely wide, and it is a good choice for entrepreneurs or processing companies.

The uv printer can print the tiles. After printing the tiles, a layer of protective layer is applied. After the uv printer prints the tiles, a layer of varnish is applied to the surface of the tiles. The effect of the varnish is mainly waterproof, scratch-resistant and beautiful.

The type of uv printer suitable for tiles is not limited. Like glazed, unglazed, matte, textured, marble and the like are common. Because the uv printer itself is not directly in contact with the tile, it is 0.5 cm away from the surface of the tile. The inkjet is used to spray the pattern on the tile surface. The non-contact printing widens the printing range of the tile.

With the innovation of technology, it has been printed in all the flat materials such as glass industry, ceramic tile industry, packaging industry, advertising production, acrylic sheet, carpet printing, mobile phone shell printing, grating plate, PVC board, canvas, Thangka, etc. The scope of application is extremely wide, and it is a good choice for entrepreneurs or processing companies.

The uv printer can print the tiles. After printing the tiles, a layer of protective layer is applied. After the uv printer prints the tiles, a layer of varnish is applied to the surface of the tiles. The effect of the varnish is mainly waterproof, scratch-resistant and beautiful.

The type of uv printer suitable for tiles is not limited. Like glazed, unglazed, matte, textured, marble and the like are common. Because the uv printer itself is not directly in contact with the tile, it is 0.5 cm away from the surface of the tile. The inkjet is used to spray the pattern on the tile surface. The non-contact printing widens the printing range of the tile.

Almost All Flat Materials Can Use Our UV Flatbed Printer

The materials that uv printers can use are very wide, up to hundreds. Almost all flat materials can use our uv flatbed printer.

1. Decoration and decoration industry

Decorations and special products are professional and personalized markets, such as: art glass, decorative ceramics, wooden crafts, furniture, fake metal plates, ceilings, curtains, etc. This market is characterized by high cost of manual processing. Low efficiency, short-running business, most suitable for digital inkjet technology. At least 30% of uv flatbed printers are currently used in a unique, personalized market.

2, signage industry

The hard signage production in the advertising, transportation, electric power and other industries is also the beneficiary of the uv flatbed printer. Compared with the traditional practice: screen printing or inkjet printing on the adhesive film material with adhesive backing, and then attaching it, reducing the process, Reduced costs and increased firmness.

3. Exhibition industry

POP display board production in the field of on-site promotion, outlet display, museum and exhibition construction is one of the most important applications of wide-format images, that is, digital inkjet, printed or screen-printed, which accounts for a wide range of images. 42% of the market. If you use UV ink to directly print on hard boards, such as KT board, acrylic board, plexiglass board, etc., it will reduce the trouble of filming, fading and foaming in the past, and save a lot of labor. Say goodbye to expensive and consume The heavy work of mounting flexible prints on rigid media.

4, rigid paper packaging industry

Another well-targeted target area for UV flatbed printers is packaging, a large industry that is expected to exceed $80 billion in the global market. At present, packaging companies that mainly use flexographic printing, screen printing and stencil printing can purchase flat-panel printers for proofing and direct output for small-volume custom customers.

5, leather textile printing industry

Traditional screen printing leather and textile printing have high requirements for plate making and quality requirements. Therefore, there are many high-end products, few middle and low-end products, and no transition colors. Leather printing using thermal transfer technology, the material becomes hard when heated, and the color changes. The weakness of these leather printing needs to be solved by new technology, that is, flat-panel printing technology.

1. Decoration and decoration industry

Decorations and special products are professional and personalized markets, such as: art glass, decorative ceramics, wooden crafts, furniture, fake metal plates, ceilings, curtains, etc. This market is characterized by high cost of manual processing. Low efficiency, short-running business, most suitable for digital inkjet technology. At least 30% of uv flatbed printers are currently used in a unique, personalized market.

2, signage industry

The hard signage production in the advertising, transportation, electric power and other industries is also the beneficiary of the uv flatbed printer. Compared with the traditional practice: screen printing or inkjet printing on the adhesive film material with adhesive backing, and then attaching it, reducing the process, Reduced costs and increased firmness.

3. Exhibition industry

POP display board production in the field of on-site promotion, outlet display, museum and exhibition construction is one of the most important applications of wide-format images, that is, digital inkjet, printed or screen-printed, which accounts for a wide range of images. 42% of the market. If you use UV ink to directly print on hard boards, such as KT board, acrylic board, plexiglass board, etc., it will reduce the trouble of filming, fading and foaming in the past, and save a lot of labor. Say goodbye to expensive and consume The heavy work of mounting flexible prints on rigid media.

4, rigid paper packaging industry

Another well-targeted target area for UV flatbed printers is packaging, a large industry that is expected to exceed $80 billion in the global market. At present, packaging companies that mainly use flexographic printing, screen printing and stencil printing can purchase flat-panel printers for proofing and direct output for small-volume custom customers.

5, leather textile printing industry

Traditional screen printing leather and textile printing have high requirements for plate making and quality requirements. Therefore, there are many high-end products, few middle and low-end products, and no transition colors. Leather printing using thermal transfer technology, the material becomes hard when heated, and the color changes. The weakness of these leather printing needs to be solved by new technology, that is, flat-panel printing technology.

What printer can print on leather?

UV

printers can print flowers on leather. In the actual printing process,

the appropriate equipment should be selected according to the material

of the leather. E.g:

1, hard leather, such as pu leather, printing, if you need to use hard ink;2, soft leather, such as leather, cowhide, etc., if printed, you need to use soft ink;If the leather is folded or bent, the pattern printed on the leather will not fade or fall off.

After a series of editing processes, it is printed on a printed object by a UV printer, such as wood, leather, and acrylic. The UV ink used, the printing is immediately dry, the printed material requirements are flat, and the common glass and tile UV leather printer is to transfer the pattern to be printed to the computer.

1, family, store decoration. The flatbed printer can print high-precision pictures on various decoration materials such as ceramic tiles, marble, paint-free panels, aluminum-plastic panels, wood panels and even walls, providing colorful content and creativity for home decoration and store decoration.

2. Advertising. The printer can be printed on the wall, acrylic, plexiglass, aluminum composite panel, two-color board, PVC board, KT board, wood board, all kinds of plastic paper, cloth, in the production of outdoor advertising, road signs, monograms and signs. It has a broad market application space.

3. Image. Printing digital images on any medium may be an application that creatively combines the style of the image with the changes in the media, so that the traditional photo is sandwiched between glass and a hard board, and then fixed in the photo frame. This method of decoration has been expanded. Such as:

1. Print images on metal plates, plastic plates, wood boards, cardboard, glass plates, ceramic plates, etc.;

2. Print high temperature permanent images on glass plates and ceramic plates;

3. Print images on various plastic paper, cloth, silk, silk, leaves, bark and other materials.

4, ready to print, T-shirt printing. As long as you have a flattenable surface on your garment, you can print it by snapping it underneath the printer. At present, there is no such a garment printer with mature technology in China. At present, garment printing is adopted by screen printing and thermal transfer. The thermal transfer printing equipment is time-consuming and laborious. The cost is high, the printing effect is not good, and there are difficulties that these printers can overcome, so there is a big market, and the prospect of the promotion and use of this printer technology is to imagine how broad it is.

5, gifts. Wrap your gift on auspicious patterns, blessing language, your or each other's images, so that you can not only fully express your feelings, but also surprise the other person and remember you, why not do it? ?

6, the craft market. Such as woodworking carving process, glass craft, hand embroidery, straw painting, stickers, pyrography, etc., these crafts must be drawn by hand before the production, some must first draw beautiful patterns before making, now, as long as You have a digital pattern, as long as there is a pattern you can get (it includes a picture that the camera can capture or downloadable on the Internet), and you want it to output to any plane, which is much stronger than hand drawing, so that If you have a Meihua flatbed printer, would you still be guilty of less skilled workers or poor skills?

7, personalized service market. If you print personalized patterns on mobile phones, laptops, hats, backpacks, satchels, handbags, etc., in this project, the revenue may be high because it is facing the end consumer, which is used by customers. Service providers print, the market development will be risky, but if done well, the profits will be high.

8 Offices of various enterprises and institutions. Such as: printing road signs, monograms; printing hard books; printing uniforms, cultural shirts, handbags; printing on the wall, printing various rules and regulations, printing business procedures, printing notices or notices, printing advertising calligraphy and painting; Or print on the glass, such as calligraphy, images, plaques, etc.

1, hard leather, such as pu leather, printing, if you need to use hard ink;2, soft leather, such as leather, cowhide, etc., if printed, you need to use soft ink;If the leather is folded or bent, the pattern printed on the leather will not fade or fall off.

After a series of editing processes, it is printed on a printed object by a UV printer, such as wood, leather, and acrylic. The UV ink used, the printing is immediately dry, the printed material requirements are flat, and the common glass and tile UV leather printer is to transfer the pattern to be printed to the computer.

1, family, store decoration. The flatbed printer can print high-precision pictures on various decoration materials such as ceramic tiles, marble, paint-free panels, aluminum-plastic panels, wood panels and even walls, providing colorful content and creativity for home decoration and store decoration.

2. Advertising. The printer can be printed on the wall, acrylic, plexiglass, aluminum composite panel, two-color board, PVC board, KT board, wood board, all kinds of plastic paper, cloth, in the production of outdoor advertising, road signs, monograms and signs. It has a broad market application space.

3. Image. Printing digital images on any medium may be an application that creatively combines the style of the image with the changes in the media, so that the traditional photo is sandwiched between glass and a hard board, and then fixed in the photo frame. This method of decoration has been expanded. Such as:

1. Print images on metal plates, plastic plates, wood boards, cardboard, glass plates, ceramic plates, etc.;

2. Print high temperature permanent images on glass plates and ceramic plates;

3. Print images on various plastic paper, cloth, silk, silk, leaves, bark and other materials.

4, ready to print, T-shirt printing. As long as you have a flattenable surface on your garment, you can print it by snapping it underneath the printer. At present, there is no such a garment printer with mature technology in China. At present, garment printing is adopted by screen printing and thermal transfer. The thermal transfer printing equipment is time-consuming and laborious. The cost is high, the printing effect is not good, and there are difficulties that these printers can overcome, so there is a big market, and the prospect of the promotion and use of this printer technology is to imagine how broad it is.

5, gifts. Wrap your gift on auspicious patterns, blessing language, your or each other's images, so that you can not only fully express your feelings, but also surprise the other person and remember you, why not do it? ?

6, the craft market. Such as woodworking carving process, glass craft, hand embroidery, straw painting, stickers, pyrography, etc., these crafts must be drawn by hand before the production, some must first draw beautiful patterns before making, now, as long as You have a digital pattern, as long as there is a pattern you can get (it includes a picture that the camera can capture or downloadable on the Internet), and you want it to output to any plane, which is much stronger than hand drawing, so that If you have a Meihua flatbed printer, would you still be guilty of less skilled workers or poor skills?

7, personalized service market. If you print personalized patterns on mobile phones, laptops, hats, backpacks, satchels, handbags, etc., in this project, the revenue may be high because it is facing the end consumer, which is used by customers. Service providers print, the market development will be risky, but if done well, the profits will be high.

8 Offices of various enterprises and institutions. Such as: printing road signs, monograms; printing hard books; printing uniforms, cultural shirts, handbags; printing on the wall, printing various rules and regulations, printing business procedures, printing notices or notices, printing advertising calligraphy and painting; Or print on the glass, such as calligraphy, images, plaques, etc.

Sunday, August 19, 2018

Friday, August 17, 2018

Thursday, August 16, 2018

CF-3020A UV flatbed printer For Guangzhou ChunYuQiuFeng

CF-3020A UV flatbed printer use Ricoh G5 print head, can print on ceramic, glass, plastic, acrylic, leather, PVC etc.

Product specifications

Model type

|

CF-3020A

|

Max thickness

|

10cm (with infrared sensor protection)

|

Max print size

|

300cm (width) * 200cm(length)

|

Structure

|

Industrial structure frame

|

X&Y Motor

|

Panasonic & Delta servo motor

|

Print head

|

4 Ricoh Gen5 industrial print heads up to 7 (optional)

|

Ink type

|

UV LED curable inks

|

Ink color

|

Standard: C,M,Y,K,White

Optional: Lc,Lm,Varnish

|

Ink capacity

|

1000ml

|

Equipment dimensions

|

463cm * 266cm * 132cm

|

Net weight

|

1100kgs

|

Technical specifications

Printing resolution

|

720 * 1200 dpi

|

Printing technology

|

Variable dot printing (grey scale printing)

|

Printing direction & speed

|

6 pass 10 ~ 12m²/hour

8 pass 8~ 10m²/ hour

|

Ink supply system

|

Negative pressure system with automatic ink system

|

UV technology

|

4 groups of UV LED water cooling lamp

|

RIP software

|

Photo print

|

Interface

|

USB 3.0

|

Power requirements

|

AC 100-110V / 220-240V 20/60Hz

|

Printing material

Metal, glass, plastics, wood, ceramic tile, acrylic, pvc, leather

Detail:

Ricoh print head: photo print rip software, steel structure, anti-corrosion, 24-hour continuous working, 3-4 years average lifetime.

Synchronous printing of white multicolor and vanish: achieve various printing patterns horizontally and vertically set the base and surface freely by white or multicolor. Largely increase the efficiency.

Vacuuming platform: adjust the vacuuming area and volume accordingly. Absorb various materials evenly and steadily. The platform is hard and corrosion-resistant. It protects the friction between the print head and media, which lengthen the lifetime of the print head.

Steel frame structure:

Apply all steel frame structure, high stability and high precision.

Negative pressure system: negative pressure system ink supply with digital control pressure display gauges ensures high-quality printing at higher possible firing frequency, hence increasing printing speed and stability.

Function of print head scratch proof:

Keeping print head from scratching or hitting when printing cortex or uneven item. When scratch proof device knock-off, it can also continue the print task, print the picture without aperture, eliminating material waste.

Industrial servo motor:

With 2 high performances industrial servo motors provide excellent control of the X and Y movement of the shuttle.

Guide rail:

Using Japan THK linear motion bearing, dual linear motion bearing provides ultra stable environment at super speed precise printing.

Subscribe to:

Posts (Atom)

How can uv flatbed printers improve production?

With the rapid advancement of technology, uv flatbed printers are becoming more and more suitable for production work with the market's...

Our uv flatbed printer machine

-

With the rapid advancement of technology, uv flatbed printers are becoming more and more suitable for production work with the market's...

-

CMYK is also known as the print color mode . The biggest difference between it and RGB is that the RGB mode is a luminescent color mode, and...

-

The Xaar 1001 printhead has many patented design techniques that lead the development of digital inkjet decoration technology in many respec...