With the rapid advancement of technology, uv flatbed printers are becoming more and more suitable for production work with the market's unique, high-precision and high-speed pursuit. Producers buy flatbed printers not only to be able to have further production power, lower production margins, but to think about how to get profit quickly, and how to make a surplus.

Before commenting on the cost of the uv flatbed printer, we must first know what invisible cost of the printing business is in production? The uv flatbed printer simply prints the cost, mainly refers to the cost per square ink, which is related to many elements:

DPI, which is the resolution. In simple words, the more dots you print per square, the more full the picture, the more ink you consume, and the number of inkjet points during this period can be close to half the difference.

Whether to spray white ink, there are some white paints on the market that need to be sprayed with white background and white paint. The price of white uv ink is higher than that of colorful uv ink. If the same DPI inkjet, you can spray a layer of white. Ink, the cost of this will be even higher.

If you print a full-color picture, the cost of printing ink is about 6-7 yuan, and the relief effect is more expensive. If you are doing a background wall, you can't buy a embossed one. You can buy a sand blasting machine and sculpt the printed picture.

Guangzhou ChunYuQiuFeng Digital color printingequipment co.,LTD, which is heexecutants of double-white embossed high speed printing, first gloss oilsolution launched company in the domestic printing industries.

Showing posts with label uv printer. Show all posts

Showing posts with label uv printer. Show all posts

Friday, November 2, 2018

Thursday, September 6, 2018

Xaar Print Head Will Become The Mainstream Print Head of UV Flatbed Printer

The Xaar 1001 printhead has many patented design techniques that lead the development of digital inkjet decoration technology in many respects, especially the superior printing results produced by the use of ink droplets to optimize grayscale technology, which highlights its outstanding leadership.

Specifically, the Xaar 1001 printhead has the advantage of having ink drop optimization technology:

This technology enables the ejection of ink droplets of various sizes and sizes on the ceramic tile, which means that the size of the ink droplets can be varied. The variable ink droplet model has the following advantages:

1) The image is more HD and sharper

The high-naturalized nozzles per inch of the Xaar 1001 printhead produce sharp, sharp droplets with a smaller ink drop pattern, which results in sharper images and sharper images during the actual printing process. Printing ink droplets of different sizes is also known as grayscale or grayscale printing technology. The original inkjet device is binary. The ink droplets printed by the two-state printing are of no size. All of them are of one model. When the printhead is printed, it only prints or does not print. In terms of image forming, the intensity and lightness of the color is achieved by the amount of ink droplets. When the image is enlarged to a certain extent, the edge of the image will form a more pronounced zigzag shape, so for some images that are relatively more demanding. It is difficult to achieve a more perfect image effect. And when the ink droplets have a different size, it can make the image more perfect.

2) Produce a wider color gamut

Another feature based on ink drop optimization technology is the automatic drop model selector. This automatic drop model selector gives the tile a different glaze depending on the degree of absorption of the tile to create a wider tile. Color gamut.

3) Grayscale printing

The ability to print ink drops that can print different sizes is called "grayscale printing." As described earlier, grayscale printing can make the pattern more perfect. The realization of gray scale is to quickly eject the ink droplets one by one after precise calculation. These small ink droplets are quickly merged into new sizes according to different requirements after leaving the nozzle, so that the ink droplets reaching the tile surface are made. Different sizes have been produced, that is, grayscale printing has been achieved.

Xaar 1001GS6 print head

In the Xaar1001GS6 printhead, each of the most basic normal printing single-shot processes can equally eject six ink droplets of the same size, and then the six drops of ink quickly merge into one drop as soon as they leave the nozzle. The most basic ink drop. When the gray level is achieved, there is one more injection process for each level, so the model of the ink drop is a multiple of 6. Then, the gray level of Xaar 1001GS6 is 0, 6, 12, 18, 24, 36, 42 ink droplets of several grades. Ink drop models are automatically selected as needed.

In fact, combining the highly natural resolution and grayscale methods, the Xaar 1001 printhead produces a resolution higher than 1000 microns, close to the human eye's recognition limit. In other words, a perfect presentation can be achieved within the normal line of sight. So, the Xaar100 1GS6 printhead can create stunning images and high-definition images.

Xaar 1001GS12 print head

According to the above analysis, the Xaar 1001GS12 printhead can eject a larger volume of ink from 12 to 84 volumes, and can spray more ink for a thicker tile color effect. As a better option, the Xaar 1001GS12 printhead produces the same ink coverage as the Xaar 1001GS6, but prints at twice the speed of the GS6.

The print quality of both printheads is much higher than that of the two-state printhead. The two-state printhead has been described above because it does not change the size of the ink droplets. However, the two models of the Sel 1001 can easily make tile manufacturers achieve excellent reproduction of natural materials such as marble and granite, as well as highly creative new designs.

Ink optimization technology

In order to achieve the high quality ceramic inks and special color effects that ceramic manufacturers want, ceramic ink manufacturers have created new inks for digital inkjet printing. To ensure that every drop of ink that is approved is ejected in the most ideal way, Xaar technology fine-tunes the way the printhead is ejected to form a data file for each type of ink. This is called: " The waveform optimization file is the waveform file. Xaar technology works closely with other components to produce a waveform of each drop, ensuring the accuracy of the drop position, optimum operating voltage, print confidence, and the most fundamental yield increase. Once successfully verified, digital ceramic inks will ensure long-term damage to the printhead, and the best waveform will produce unparalleled print results and double savings in operating costs.

This is not difficult to understand, because the basic physical and chemical properties of each type of ink are different, such as the viscosity, specific gravity of the ink, and so on. As mentioned above, the nozzle is a very precise and precise process when it is working, so that the tiny droplets are combined in the short time and short distance and accurately placed in the corresponding position. It is necessary to have a very accurate calculation of the entire printing process to be realized, so any small data influence can cause errors in this process, resulting in deviation of ink droplets. Therefore, the nozzle requires very detailed performance testing and data analysis for each drop of ink. The data file corresponding to each drop of ink is what we call the waveform file, which is why Serge has always insisted that customers use the correct waveform file. (The wave file is described in detail later)

Our Chunyuqiufeng CF-1016 UV flatbed printer uses the Xaar 1201 printhead.

High print quality, highly versatile and easy to integrate

The Xaar 1201 is a Thin Film Piezo Silicon Micro Electrical Mechanical System (MEMS) technology printhead for printing wide-format graphics (WFG) and textiles with dye sublimation, eco-solvent, UV or aqueous inks. It has 1280 nozzles arranged in 4 rows Printing either 1 or 2 colours at 600 dpi or 4 colours at 300 dpi native resolution.

This is the perfect printhead for OEMs looking to design graphics printers for banners, signage and POS applications because it delivers a high quality of print combined with high productivity and is easy to integrate; therefore time-to-market is minimised.

The Xaar 1201 gives OEMs an assured supply and reputable, quality printhead for the WFG and textiles markets. High print speed, high accuracy and reliability are achieved by the MEMS technology making the Xaar 1201 printhead suitable for either static or multi-pass scanning applications.

All in all, Xaar's unique waveforms and qualified inks guarantee the best quality and maximum usable time.

Specifically, the Xaar 1001 printhead has the advantage of having ink drop optimization technology:

This technology enables the ejection of ink droplets of various sizes and sizes on the ceramic tile, which means that the size of the ink droplets can be varied. The variable ink droplet model has the following advantages:

1) The image is more HD and sharper

The high-naturalized nozzles per inch of the Xaar 1001 printhead produce sharp, sharp droplets with a smaller ink drop pattern, which results in sharper images and sharper images during the actual printing process. Printing ink droplets of different sizes is also known as grayscale or grayscale printing technology. The original inkjet device is binary. The ink droplets printed by the two-state printing are of no size. All of them are of one model. When the printhead is printed, it only prints or does not print. In terms of image forming, the intensity and lightness of the color is achieved by the amount of ink droplets. When the image is enlarged to a certain extent, the edge of the image will form a more pronounced zigzag shape, so for some images that are relatively more demanding. It is difficult to achieve a more perfect image effect. And when the ink droplets have a different size, it can make the image more perfect.

2) Produce a wider color gamut

Another feature based on ink drop optimization technology is the automatic drop model selector. This automatic drop model selector gives the tile a different glaze depending on the degree of absorption of the tile to create a wider tile. Color gamut.

3) Grayscale printing

The ability to print ink drops that can print different sizes is called "grayscale printing." As described earlier, grayscale printing can make the pattern more perfect. The realization of gray scale is to quickly eject the ink droplets one by one after precise calculation. These small ink droplets are quickly merged into new sizes according to different requirements after leaving the nozzle, so that the ink droplets reaching the tile surface are made. Different sizes have been produced, that is, grayscale printing has been achieved.

Xaar 1001GS6 print head

In the Xaar1001GS6 printhead, each of the most basic normal printing single-shot processes can equally eject six ink droplets of the same size, and then the six drops of ink quickly merge into one drop as soon as they leave the nozzle. The most basic ink drop. When the gray level is achieved, there is one more injection process for each level, so the model of the ink drop is a multiple of 6. Then, the gray level of Xaar 1001GS6 is 0, 6, 12, 18, 24, 36, 42 ink droplets of several grades. Ink drop models are automatically selected as needed.

In fact, combining the highly natural resolution and grayscale methods, the Xaar 1001 printhead produces a resolution higher than 1000 microns, close to the human eye's recognition limit. In other words, a perfect presentation can be achieved within the normal line of sight. So, the Xaar100 1GS6 printhead can create stunning images and high-definition images.

Xaar 1001GS12 print head

According to the above analysis, the Xaar 1001GS12 printhead can eject a larger volume of ink from 12 to 84 volumes, and can spray more ink for a thicker tile color effect. As a better option, the Xaar 1001GS12 printhead produces the same ink coverage as the Xaar 1001GS6, but prints at twice the speed of the GS6.

The print quality of both printheads is much higher than that of the two-state printhead. The two-state printhead has been described above because it does not change the size of the ink droplets. However, the two models of the Sel 1001 can easily make tile manufacturers achieve excellent reproduction of natural materials such as marble and granite, as well as highly creative new designs.

Ink optimization technology

In order to achieve the high quality ceramic inks and special color effects that ceramic manufacturers want, ceramic ink manufacturers have created new inks for digital inkjet printing. To ensure that every drop of ink that is approved is ejected in the most ideal way, Xaar technology fine-tunes the way the printhead is ejected to form a data file for each type of ink. This is called: " The waveform optimization file is the waveform file. Xaar technology works closely with other components to produce a waveform of each drop, ensuring the accuracy of the drop position, optimum operating voltage, print confidence, and the most fundamental yield increase. Once successfully verified, digital ceramic inks will ensure long-term damage to the printhead, and the best waveform will produce unparalleled print results and double savings in operating costs.

This is not difficult to understand, because the basic physical and chemical properties of each type of ink are different, such as the viscosity, specific gravity of the ink, and so on. As mentioned above, the nozzle is a very precise and precise process when it is working, so that the tiny droplets are combined in the short time and short distance and accurately placed in the corresponding position. It is necessary to have a very accurate calculation of the entire printing process to be realized, so any small data influence can cause errors in this process, resulting in deviation of ink droplets. Therefore, the nozzle requires very detailed performance testing and data analysis for each drop of ink. The data file corresponding to each drop of ink is what we call the waveform file, which is why Serge has always insisted that customers use the correct waveform file. (The wave file is described in detail later)

Our Chunyuqiufeng CF-1016 UV flatbed printer uses the Xaar 1201 printhead.

High print quality, highly versatile and easy to integrate

The Xaar 1201 is a Thin Film Piezo Silicon Micro Electrical Mechanical System (MEMS) technology printhead for printing wide-format graphics (WFG) and textiles with dye sublimation, eco-solvent, UV or aqueous inks. It has 1280 nozzles arranged in 4 rows Printing either 1 or 2 colours at 600 dpi or 4 colours at 300 dpi native resolution.

This is the perfect printhead for OEMs looking to design graphics printers for banners, signage and POS applications because it delivers a high quality of print combined with high productivity and is easy to integrate; therefore time-to-market is minimised.

The Xaar 1201 gives OEMs an assured supply and reputable, quality printhead for the WFG and textiles markets. High print speed, high accuracy and reliability are achieved by the MEMS technology making the Xaar 1201 printhead suitable for either static or multi-pass scanning applications.

All in all, Xaar's unique waveforms and qualified inks guarantee the best quality and maximum usable time.

Tuesday, September 4, 2018

What are UV Flatbed and Flatbed Printers?

Customers who need to purchase a machine usually contact a lot of manufacturers for consultation. It is understood that there are quite a few customers who have consulted the price difference is very large, and the same size.

Some manufacturers confuse UV with the tablet, misleading customers who do not understand and do not understand, here is the difference between UV and tablet in inkjet printers.

1.The name and name of this inkjet printer is completely different. Some manufacturers are called UV printers, universal printers, universal flatbed printers, UV inkjet printers, digital printers, digital printers, etc.

There are a lot of names, and the whole can be divided into two categories,

1: UV series, 2: flat series.

2.The main difference lies in the process: the flat series machines are mainly modified by Epson. The printed products are weak solvent inks. Many products have restrictions, and the process is more troublesome.

Is it better to choose a flat series or a UV series?

Now more than 85% of customers who buy machines will choose UV. The flat series is a very early machine. Of course, there will be customers to choose from. The main white leather products and the products used in white can also choose the flat series. Other products are directly recommended to choose the UV series.

Some manufacturers confuse UV with the tablet, misleading customers who do not understand and do not understand, here is the difference between UV and tablet in inkjet printers.

|

| CF-1016 UV Flatbed Printer |

1.The name and name of this inkjet printer is completely different. Some manufacturers are called UV printers, universal printers, universal flatbed printers, UV inkjet printers, digital printers, digital printers, etc.

There are a lot of names, and the whole can be divided into two categories,

1: UV series, 2: flat series.

2.The main difference lies in the process: the flat series machines are mainly modified by Epson. The printed products are weak solvent inks. Many products have restrictions, and the process is more troublesome.

- The surface of the printed product must be coated, otherwise the adhesion is not enough, and the printed matter is easy to fade;

- It is limited to products that bring you white background, because the weak solvent ink is not white;

- Only products that are used indoors are printed, because weak solvent inks are not UV-resistant, and if placed outdoors, the color may become lighter or even faded after a few months;

- The printed product is not ready to be dried, needs to be baked or naturally dried.

- Can not print embossed three-dimensional feel;

- The printing speed is relatively slower than UV, generally printing about 5 square meters per hour. In general, the difference between UV and flat on the process: the UV process is simple, most products can be printed, and the tablet is more troublesome to be coated. Layer, many products are limited.

- The UV series of machines are mainly based on process machines. They use independent nozzles. Each color uses one nozzle or two colors to control printing with one nozzle. The ink printed is UV ink. With UV UV curing system, the product can be color-free, and it can be printed directly in black, dark and transparent colors.

- The printing UV ink can be applied indoors and outdoors, and there is no problem in the sun, the wind and the rain.

- The process is simple, more than 90% of the products are directly printed without coating treatment, and they are ready to be dried, and the finished product is finished.

- The mainstream 3D relief effect is easy to implement.

- Industrial-grade nozzles print faster at speeds, typically ranging from 10-20 square meters per hour. The main disadvantage is that the printing cost is relatively high: the cost per square meter of color printing is about 3-5 yuan, and the UV relief printing is about 10-20 yuan.

|

| TaiWan Ink |

Now more than 85% of customers who buy machines will choose UV. The flat series is a very early machine. Of course, there will be customers to choose from. The main white leather products and the products used in white can also choose the flat series. Other products are directly recommended to choose the UV series.

Sunday, August 26, 2018

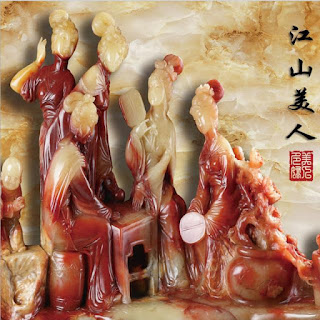

UV Flatbed Printer With 3D Background Wall Part.2

Background wall UV printer features:

1. The printing effect is beautiful and the alignment is accurate and no scrap.

2. The printed format can be large or small. The common 600*600mm and 800*800mm tiles can be processed in the market, and the printing is completed once.

3. The printing cost is low, which can reduce the printing cost.

4. Strong stability, solves the shortcomings of common flatbed printers.

5. No need to make plate printing and repeat color registration, simple and convenient, can save more than 80% of the cost compared with the traditional process.

Common noun analysis:

Art flower carving: The art flower carving pattern content is mainly composed of lines and patterns. The pattern lines are mainly composed of modern lines, European patterns, object wire frames, etc. The conventional method is to engrave the pattern elements and then carry out artificial inkjet printing. Silver paint, the effect of this process on the bright surface material is high-grade and elegant.

Three-dimensional micro-carving: The three-dimensional micro-carving production process is rather cumbersome. It is necessary to carry out a very fine engraving process on the brick surface. After that, it is also required to make multiple films according to the pattern composition, and then accurately position the wall-mounted UV flatbed printer for 3D stereo high-definition inkjet. The final effect can achieve the effect of 1:1 ratio reduction oil brush touch, suitable for engraving of oil painting, upper freehand drawing and so on.

Flat color printing: The surface of the carved tile is coated, then inkjet printing is performed on the UV printer on the background wall, and finally a layer of varnish (or varnish) is applied on the surface to better protect the surface of the wall.

Symphony: Multi-layered engraving on the surface of the tile. After completion, there are a number of concave and convex layers and the theme part is all convex. The relief and the engraving can engrave the complex picture engraving and engrave multiple independent layers. The three-dimensionality of the picture is unmistakable and the expression is excellent.

Magical carving: Engraving on the surface of the tile, this is more complicated and requires a certain amount of technical content. After the engraving is completed, there are a plurality of different concave and convex layers, which have strong stereoscopic effect and good performance, and are suitable for various styles. The background wall image is engraved with a very fine detail, and the fine details in the pattern can be carved out. For example, the feathers of birds, the petals of flowers, the stamens, etc. in the paintings of flowers and birds, the carving requirements are high, and the production process is complicated.

Magical Art Carving: Art carving on the brick surface, suitable for the layered picture of the elements in the content, the art carving can engrave the three-dimensional and artistic sense of the theme part very carefully, generally retain some brick surface, the brick surface The combination of texture and picture makes the overall picture harmonious and integrated.

1. The printing effect is beautiful and the alignment is accurate and no scrap.

2. The printed format can be large or small. The common 600*600mm and 800*800mm tiles can be processed in the market, and the printing is completed once.

3. The printing cost is low, which can reduce the printing cost.

4. Strong stability, solves the shortcomings of common flatbed printers.

5. No need to make plate printing and repeat color registration, simple and convenient, can save more than 80% of the cost compared with the traditional process.

Common noun analysis:

Art flower carving: The art flower carving pattern content is mainly composed of lines and patterns. The pattern lines are mainly composed of modern lines, European patterns, object wire frames, etc. The conventional method is to engrave the pattern elements and then carry out artificial inkjet printing. Silver paint, the effect of this process on the bright surface material is high-grade and elegant.

Three-dimensional micro-carving: The three-dimensional micro-carving production process is rather cumbersome. It is necessary to carry out a very fine engraving process on the brick surface. After that, it is also required to make multiple films according to the pattern composition, and then accurately position the wall-mounted UV flatbed printer for 3D stereo high-definition inkjet. The final effect can achieve the effect of 1:1 ratio reduction oil brush touch, suitable for engraving of oil painting, upper freehand drawing and so on.

Flat color printing: The surface of the carved tile is coated, then inkjet printing is performed on the UV printer on the background wall, and finally a layer of varnish (or varnish) is applied on the surface to better protect the surface of the wall.

Symphony: Multi-layered engraving on the surface of the tile. After completion, there are a number of concave and convex layers and the theme part is all convex. The relief and the engraving can engrave the complex picture engraving and engrave multiple independent layers. The three-dimensionality of the picture is unmistakable and the expression is excellent.

Magical carving: Engraving on the surface of the tile, this is more complicated and requires a certain amount of technical content. After the engraving is completed, there are a plurality of different concave and convex layers, which have strong stereoscopic effect and good performance, and are suitable for various styles. The background wall image is engraved with a very fine detail, and the fine details in the pattern can be carved out. For example, the feathers of birds, the petals of flowers, the stamens, etc. in the paintings of flowers and birds, the carving requirements are high, and the production process is complicated.

Magical Art Carving: Art carving on the brick surface, suitable for the layered picture of the elements in the content, the art carving can engrave the three-dimensional and artistic sense of the theme part very carefully, generally retain some brick surface, the brick surface The combination of texture and picture makes the overall picture harmonious and integrated.

Wednesday, August 22, 2018

How To Choose A UV Printer?

At present, with the rise of environmental protection printing, UV printing has received the attention of inkjet companies in the coming months. What kind of UV printers are good? Objectively speaking, UV printers of various manufacturers have their own advantages, and there is no absolute. Good, which one is absolutely bad. What kind of equipment is good? What suits you is the best. This issue of Xiaobian shares how to choose the right UV printer from three aspects.

The substrate is fundamental: different UV printers print different precision, pattern color, speed, consumable cost, and special effects. Then, when selecting equipment, customers should start from their own production, process requirements, and consumable expenses. Compared with multiple manufacturers, it is best to test various data on the spot so that you can choose better.

Service is king: the after-sales service provided by UV printers is king. Various sizes of problems occur during the use of the device. Regular manufacturers will provide professional training for 7-15 days before customers purchase equipment. On the one hand, it teaches customers how to use UV flatbed printers, and on the other hand, how to repair UV printers. Training videos such as text, video, and remote are also available during the later use.

The substrate is fundamental: different UV printers print different precision, pattern color, speed, consumable cost, and special effects. Then, when selecting equipment, customers should start from their own production, process requirements, and consumable expenses. Compared with multiple manufacturers, it is best to test various data on the spot so that you can choose better.

Service is king: the after-sales service provided by UV printers is king. Various sizes of problems occur during the use of the device. Regular manufacturers will provide professional training for 7-15 days before customers purchase equipment. On the one hand, it teaches customers how to use UV flatbed printers, and on the other hand, how to repair UV printers. Training videos such as text, video, and remote are also available during the later use.

10 Questions About Printheads You Need To Know Before Purchasing UV Printer

When you are buying a new UV Printer, you should ask some basic questions about its printhead.

1. Which brand and which type of printhead does the printer use?Most sellers will usually tell you the brand of the printhead when you ask for the printhead, not the detailed model of the printhead.For example, Ricoh nozzles commonly used in the market, Ricoh GEN5 nozzles and Ricoh GH2220 nozzles, Ricoh GEN5 nozzles are divided into water and oil, long and short lines, two channels and four channels.Second, is this printhead designed for solvent ink, or is it designed for UV ink?Some printheads were not originally made to print UV ink.

2.An early example of Epson sprinklers was an example. At the time, Epson itself did not produce UV-curable printers. Epson only produced water-based and solvent-based printers for photo printers and art. This does not mean that they cannot spray UV-curable inks, which only means that the nozzles may require special inks.Therefore, this question helps you understand whether the printhead is designed from the ground up for printing UV ink.

3. How many other printers use the same printhead? Do they have any questions?Konica Minolta nozzles, Ricoh nozzles, Kyocera nozzles, Xaar nozzles and starlight nozzles are all piezoelectric printheads. These are industrial strength piezoelectric printheads compared to Epson piezo printheads.

4. How many nozzles are there for each printhead?This can help you understand the speed or speed of your printer.

5. What is the total number of nozzles in the printer?The nozzle has a single nozzle that can only spray one color of the single color nozzle, and one nozzle can spray multiple colors of the multi-color nozzle.Take the Ricoh GEN5 nozzle as an example. It has two channels and four channels. When using it on a machine, you can print only one color for one nozzle, or two colors for one nozzle (two channels and four channels). Yes, you can print four colors (four-channel nozzle) in one nozzle.

6. How many printheads are there for each color?This will explain more about how slow or how fast your printer can eject ink.

7. How many skins are the ink droplets on the nozzle? Is there a variable droplet capability?The smaller the droplet, the better the print quality. However, a smaller drop size can slow down the printhead system. Similarly, printheads that produce larger drop sizes do not provide the same print quality, but print speeds tend to be better.

8. Is there a special white ink or varnish nozzle? Are they the same model as the CMYK printhead?Because the use of larger nozzles can make white inks better, some printers only have white ink to have "white droplet size is good". Other printers use the same header for any and all colors. For varnish, it is best to ask experienced printer operators and printer designers which head is best for varnish. Processing varnish is not as easy as handling ink. On a comparable basis, make sure your white ink has a recirculation system (otherwise white particles will precipitate and clog the nozzles).

9. If this piezoelectric head fails, who is responsible for paying the replacement head? What are the most common causes of printhead failure? What are the causes of the warranty? Which printhead failure causes are not covered by the warranty? Is there a limit to the number of printhead failures covered per unit time?In the case of a user-induced failure, most manufacturers will ask the user to pay for the replacement of the printhead. Most faults are indeed user errors, the most common cause being head impact.

10. What is the print height of the nozzle? Can I avoid nozzle impact?Impact is the most common cause of premature nozzle damage (improper media loading can cause bending, media rubbing onto a fragile nozzle plate, or not properly passing through the printer). A head impact can damage only a few nozzles, or it can damage the entire nozzle. Another reason is the continuous flushing, which can damage the nozzle system.

1. Which brand and which type of printhead does the printer use?Most sellers will usually tell you the brand of the printhead when you ask for the printhead, not the detailed model of the printhead.For example, Ricoh nozzles commonly used in the market, Ricoh GEN5 nozzles and Ricoh GH2220 nozzles, Ricoh GEN5 nozzles are divided into water and oil, long and short lines, two channels and four channels.Second, is this printhead designed for solvent ink, or is it designed for UV ink?Some printheads were not originally made to print UV ink.

2.An early example of Epson sprinklers was an example. At the time, Epson itself did not produce UV-curable printers. Epson only produced water-based and solvent-based printers for photo printers and art. This does not mean that they cannot spray UV-curable inks, which only means that the nozzles may require special inks.Therefore, this question helps you understand whether the printhead is designed from the ground up for printing UV ink.

3. How many other printers use the same printhead? Do they have any questions?Konica Minolta nozzles, Ricoh nozzles, Kyocera nozzles, Xaar nozzles and starlight nozzles are all piezoelectric printheads. These are industrial strength piezoelectric printheads compared to Epson piezo printheads.

4. How many nozzles are there for each printhead?This can help you understand the speed or speed of your printer.

5. What is the total number of nozzles in the printer?The nozzle has a single nozzle that can only spray one color of the single color nozzle, and one nozzle can spray multiple colors of the multi-color nozzle.Take the Ricoh GEN5 nozzle as an example. It has two channels and four channels. When using it on a machine, you can print only one color for one nozzle, or two colors for one nozzle (two channels and four channels). Yes, you can print four colors (four-channel nozzle) in one nozzle.

6. How many printheads are there for each color?This will explain more about how slow or how fast your printer can eject ink.

7. How many skins are the ink droplets on the nozzle? Is there a variable droplet capability?The smaller the droplet, the better the print quality. However, a smaller drop size can slow down the printhead system. Similarly, printheads that produce larger drop sizes do not provide the same print quality, but print speeds tend to be better.

8. Is there a special white ink or varnish nozzle? Are they the same model as the CMYK printhead?Because the use of larger nozzles can make white inks better, some printers only have white ink to have "white droplet size is good". Other printers use the same header for any and all colors. For varnish, it is best to ask experienced printer operators and printer designers which head is best for varnish. Processing varnish is not as easy as handling ink. On a comparable basis, make sure your white ink has a recirculation system (otherwise white particles will precipitate and clog the nozzles).

9. If this piezoelectric head fails, who is responsible for paying the replacement head? What are the most common causes of printhead failure? What are the causes of the warranty? Which printhead failure causes are not covered by the warranty? Is there a limit to the number of printhead failures covered per unit time?In the case of a user-induced failure, most manufacturers will ask the user to pay for the replacement of the printhead. Most faults are indeed user errors, the most common cause being head impact.

10. What is the print height of the nozzle? Can I avoid nozzle impact?Impact is the most common cause of premature nozzle damage (improper media loading can cause bending, media rubbing onto a fragile nozzle plate, or not properly passing through the printer). A head impact can damage only a few nozzles, or it can damage the entire nozzle. Another reason is the continuous flushing, which can damage the nozzle system.

Monday, August 20, 2018

Can I print tiles with a uv printer?

UV flatbed printer, also known as universal flatbed printer or flatbed printer, breaks through the bottleneck of digital printing technology, and realizes a true printing, no plate making, full color image printing once, which has many advantages over traditional printing technology.

With the innovation of technology, it has been printed in all the flat materials such as glass industry, ceramic tile industry, packaging industry, advertising production, acrylic sheet, carpet printing, mobile phone shell printing, grating plate, PVC board, canvas, Thangka, etc. The scope of application is extremely wide, and it is a good choice for entrepreneurs or processing companies.

The uv printer can print the tiles. After printing the tiles, a layer of protective layer is applied. After the uv printer prints the tiles, a layer of varnish is applied to the surface of the tiles. The effect of the varnish is mainly waterproof, scratch-resistant and beautiful.

The type of uv printer suitable for tiles is not limited. Like glazed, unglazed, matte, textured, marble and the like are common. Because the uv printer itself is not directly in contact with the tile, it is 0.5 cm away from the surface of the tile. The inkjet is used to spray the pattern on the tile surface. The non-contact printing widens the printing range of the tile.

With the innovation of technology, it has been printed in all the flat materials such as glass industry, ceramic tile industry, packaging industry, advertising production, acrylic sheet, carpet printing, mobile phone shell printing, grating plate, PVC board, canvas, Thangka, etc. The scope of application is extremely wide, and it is a good choice for entrepreneurs or processing companies.

The uv printer can print the tiles. After printing the tiles, a layer of protective layer is applied. After the uv printer prints the tiles, a layer of varnish is applied to the surface of the tiles. The effect of the varnish is mainly waterproof, scratch-resistant and beautiful.

The type of uv printer suitable for tiles is not limited. Like glazed, unglazed, matte, textured, marble and the like are common. Because the uv printer itself is not directly in contact with the tile, it is 0.5 cm away from the surface of the tile. The inkjet is used to spray the pattern on the tile surface. The non-contact printing widens the printing range of the tile.

Almost All Flat Materials Can Use Our UV Flatbed Printer

The materials that uv printers can use are very wide, up to hundreds. Almost all flat materials can use our uv flatbed printer.

1. Decoration and decoration industry

Decorations and special products are professional and personalized markets, such as: art glass, decorative ceramics, wooden crafts, furniture, fake metal plates, ceilings, curtains, etc. This market is characterized by high cost of manual processing. Low efficiency, short-running business, most suitable for digital inkjet technology. At least 30% of uv flatbed printers are currently used in a unique, personalized market.

2, signage industry

The hard signage production in the advertising, transportation, electric power and other industries is also the beneficiary of the uv flatbed printer. Compared with the traditional practice: screen printing or inkjet printing on the adhesive film material with adhesive backing, and then attaching it, reducing the process, Reduced costs and increased firmness.

3. Exhibition industry

POP display board production in the field of on-site promotion, outlet display, museum and exhibition construction is one of the most important applications of wide-format images, that is, digital inkjet, printed or screen-printed, which accounts for a wide range of images. 42% of the market. If you use UV ink to directly print on hard boards, such as KT board, acrylic board, plexiglass board, etc., it will reduce the trouble of filming, fading and foaming in the past, and save a lot of labor. Say goodbye to expensive and consume The heavy work of mounting flexible prints on rigid media.

4, rigid paper packaging industry

Another well-targeted target area for UV flatbed printers is packaging, a large industry that is expected to exceed $80 billion in the global market. At present, packaging companies that mainly use flexographic printing, screen printing and stencil printing can purchase flat-panel printers for proofing and direct output for small-volume custom customers.

5, leather textile printing industry

Traditional screen printing leather and textile printing have high requirements for plate making and quality requirements. Therefore, there are many high-end products, few middle and low-end products, and no transition colors. Leather printing using thermal transfer technology, the material becomes hard when heated, and the color changes. The weakness of these leather printing needs to be solved by new technology, that is, flat-panel printing technology.

1. Decoration and decoration industry

Decorations and special products are professional and personalized markets, such as: art glass, decorative ceramics, wooden crafts, furniture, fake metal plates, ceilings, curtains, etc. This market is characterized by high cost of manual processing. Low efficiency, short-running business, most suitable for digital inkjet technology. At least 30% of uv flatbed printers are currently used in a unique, personalized market.

2, signage industry

The hard signage production in the advertising, transportation, electric power and other industries is also the beneficiary of the uv flatbed printer. Compared with the traditional practice: screen printing or inkjet printing on the adhesive film material with adhesive backing, and then attaching it, reducing the process, Reduced costs and increased firmness.

3. Exhibition industry

POP display board production in the field of on-site promotion, outlet display, museum and exhibition construction is one of the most important applications of wide-format images, that is, digital inkjet, printed or screen-printed, which accounts for a wide range of images. 42% of the market. If you use UV ink to directly print on hard boards, such as KT board, acrylic board, plexiglass board, etc., it will reduce the trouble of filming, fading and foaming in the past, and save a lot of labor. Say goodbye to expensive and consume The heavy work of mounting flexible prints on rigid media.

4, rigid paper packaging industry

Another well-targeted target area for UV flatbed printers is packaging, a large industry that is expected to exceed $80 billion in the global market. At present, packaging companies that mainly use flexographic printing, screen printing and stencil printing can purchase flat-panel printers for proofing and direct output for small-volume custom customers.

5, leather textile printing industry

Traditional screen printing leather and textile printing have high requirements for plate making and quality requirements. Therefore, there are many high-end products, few middle and low-end products, and no transition colors. Leather printing using thermal transfer technology, the material becomes hard when heated, and the color changes. The weakness of these leather printing needs to be solved by new technology, that is, flat-panel printing technology.

Sunday, August 19, 2018

Thursday, August 16, 2018

CF-3020A UV flatbed printer For Guangzhou ChunYuQiuFeng

CF-3020A UV flatbed printer use Ricoh G5 print head, can print on ceramic, glass, plastic, acrylic, leather, PVC etc.

Product specifications

Model type

|

CF-3020A

|

Max thickness

|

10cm (with infrared sensor protection)

|

Max print size

|

300cm (width) * 200cm(length)

|

Structure

|

Industrial structure frame

|

X&Y Motor

|

Panasonic & Delta servo motor

|

Print head

|

4 Ricoh Gen5 industrial print heads up to 7 (optional)

|

Ink type

|

UV LED curable inks

|

Ink color

|

Standard: C,M,Y,K,White

Optional: Lc,Lm,Varnish

|

Ink capacity

|

1000ml

|

Equipment dimensions

|

463cm * 266cm * 132cm

|

Net weight

|

1100kgs

|

Technical specifications

Printing resolution

|

720 * 1200 dpi

|

Printing technology

|

Variable dot printing (grey scale printing)

|

Printing direction & speed

|

6 pass 10 ~ 12m²/hour

8 pass 8~ 10m²/ hour

|

Ink supply system

|

Negative pressure system with automatic ink system

|

UV technology

|

4 groups of UV LED water cooling lamp

|

RIP software

|

Photo print

|

Interface

|

USB 3.0

|

Power requirements

|

AC 100-110V / 220-240V 20/60Hz

|

Printing material

Metal, glass, plastics, wood, ceramic tile, acrylic, pvc, leather

Detail:

Ricoh print head: photo print rip software, steel structure, anti-corrosion, 24-hour continuous working, 3-4 years average lifetime.

Synchronous printing of white multicolor and vanish: achieve various printing patterns horizontally and vertically set the base and surface freely by white or multicolor. Largely increase the efficiency.

Vacuuming platform: adjust the vacuuming area and volume accordingly. Absorb various materials evenly and steadily. The platform is hard and corrosion-resistant. It protects the friction between the print head and media, which lengthen the lifetime of the print head.

Steel frame structure:

Apply all steel frame structure, high stability and high precision.

Negative pressure system: negative pressure system ink supply with digital control pressure display gauges ensures high-quality printing at higher possible firing frequency, hence increasing printing speed and stability.

Function of print head scratch proof:

Keeping print head from scratching or hitting when printing cortex or uneven item. When scratch proof device knock-off, it can also continue the print task, print the picture without aperture, eliminating material waste.

Industrial servo motor:

With 2 high performances industrial servo motors provide excellent control of the X and Y movement of the shuttle.

Guide rail:

Using Japan THK linear motion bearing, dual linear motion bearing provides ultra stable environment at super speed precise printing.

Subscribe to:

Posts (Atom)

How can uv flatbed printers improve production?

With the rapid advancement of technology, uv flatbed printers are becoming more and more suitable for production work with the market's...

Our uv flatbed printer machine

-

With the rapid advancement of technology, uv flatbed printers are becoming more and more suitable for production work with the market's...

-

The Xaar 1001 printhead has many patented design techniques that lead the development of digital inkjet decoration technology in many respec...

-

We all know that inkjet printheads can be divided into oily printheads, water-based printheads, and water-oil general-purpose printheads , d...